Walmart, RFID, and the New Retail Strategy

12/07/2025

Walmart is the world’s largest retailer and is widely recognized as a master of supply chain management. It has achieved this reputation by efficiently handling a massive volume of goods while still delivering them to customers quickly and at the lowest possible cost.

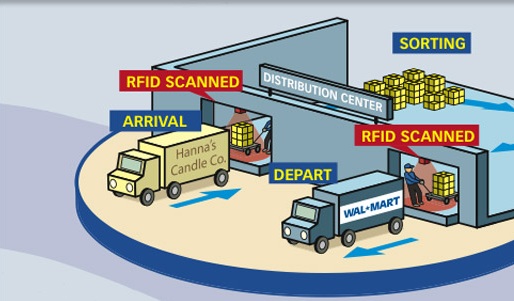

To ensure its supply chain operates effectively, Walmart has consistently led the way in adopting new technologies. Among these, RFID has proven to be one of the most successful solutions, significantly improving supply chain efficiency, enhancing inventory management, and enabling accurate customer demand forecasting for better production planning.

Walmart’s RFID Program

RFID (Radio Frequency Identification) is a technology that identifies goods using radio waves. Tiny RFID chips are embedded in product labels and respond to radio signals from reading devices. This identification process takes only a few seconds, significantly reducing inventory time, increasing staff productivity, and enabling real-time product tracking.

Walmart has launched an RFID program that requires all of its suppliers to tag each item sold in its stores, starting with the apparel category. More recently, Walmart has expanded the program to include other categories such as home goods, sporting equipment, electronics, and toys. Suppliers in these categories were required to meet Walmart’s RFID tagging standards by September 2, 2022.

Benefits RFID Brings to Walmart

Rollin Ford, Walmart’s former Chief Supply Chain Officer, stated:

“We used to count every item individually, and scanning each one was a challenge. Now, with RFID, we can scan an entire pallet and instantly know exactly how many items are there, from color to condition. This greatly simplifies receiving. RFID also allows us to reorganize the supply chain more quickly when responding to events.”

RFID has made Walmart’s inventory management faster and more efficient than ever. The company has saved significant labor and time costs at both warehouses and retail locations. A single RFID reader can capture data from all the packages in a warehouse without needing to move or manually scan barcodes. At the same time, Walmart can track every package in real time. If something goes missing, they can instantly identify what it was thanks to each item’s unique RFID tag.

RFID and Beyond Supply Chain Management

Walmart hasn’t limited RFID to internal supply chain use. It has expanded its application by connecting its system with suppliers, such as Procter & Gamble (P&G). The two giants developed a software system linking P&G’s operations directly to Walmart’s distribution centers. With real-time data on product sales and inventory levels at Walmart stores, P&G can adjust production accordingly, ensuring products are always in stock.

This integration has enabled P&G to cut down on lead time, minimize inventory levels, and reduce order processing costs within Walmart’s system—contributing to Walmart’s long-standing promise of “Low prices every day.”

RFID represents a breakthrough improvement in Walmart’s supply chain management compared to traditional barcode systems. With this technology, Walmart has saved considerable time and labor, enabling smarter supply chain operations and moving closer to its New Retail vision—cementing its position as the undisputed giant of global retail.

Related Articles

- 1Gate’s RFID-Based Traceability & Anti-Counterfeiting System

- Hệ thống truy xuất nguồn gốc và chống giả 1Gate

- RFID Applications in Steel Manufacturing Plants

- Choosing RFID Tags for Metal Surfaces – What You Need to Know

- UNIQLO Implements RFID on a Global Scale

- Ứng dụng RFID trong nhà máy sắt thép

- Lựa chọn thẻ RFID gắn trên kim loại- Những điều cần lưu ý

- UNIQLO áp dụng RFID trên phạm vi toàn cầu

- Wallmart, RFID và chiến lược New Retail