UNIQLO Implements RFID on a Global Scale

12/07/2025

In 2017, Japan’s fast fashion giant Fast Retailing Group—the parent company of UNIQLO—announced the adoption of RFID technology across 3,000 stores worldwide.

UNIQLO became the first retail brand in Japan to implement RFID tagging on a global scale. However, its competitors had already taken steps in this direction: H&M began using RFID in 2014, and Zara rolled out its RFID system in 2017.

Beyond simply tagging all products with RFID, UNIQLO has actively integrated the technology into other retail functions, including smart fitting rooms, product information kiosks, and self-checkout counters. These efforts are part of its New Retail strategy, which aims to optimize operations and shorten the time from production to end customer.

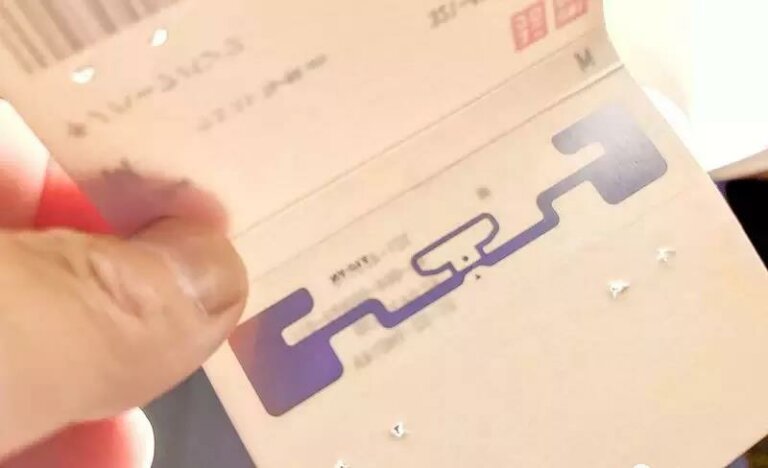

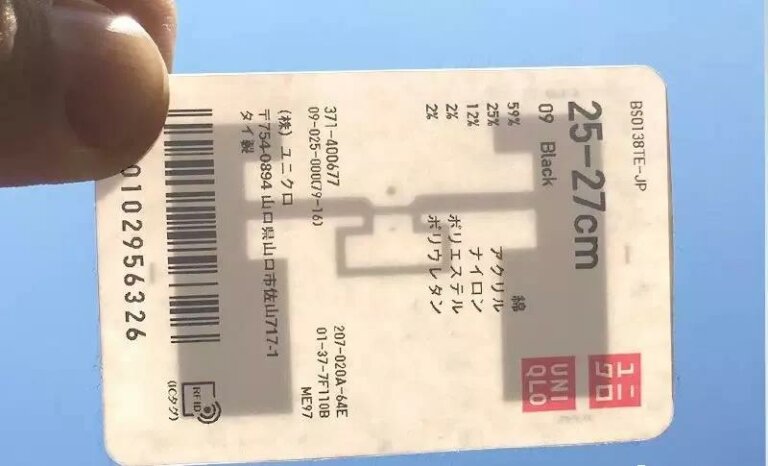

1. Product-Level RFID Tagging

Compared to barcode systems that require manual scanning, RFID tags can automatically capture data quickly and accurately—saving labor and reducing warehouse costs. RFID tags can also store more detailed information such as style, color, and size, enabling faster access to product details and more informed decision-making.

Depending on the size and characteristics of each product, UNIQLO uses various types of RFID tags with different shapes, sizes, and designs.

2. Information Display

Shoppers simply select and try on products in front of a digital screen. The screen also allows users to check product information in their shopping cart by automatically reading data from the RFID tags attached to the items.

3. Self-Checkout with RFID

In addition, UNIQLO has implemented self-checkout counters using RFID technology. After completing their shopping, customers place their clothing items onto the RFID checkout area. The self-checkout machine then scans the items and instantly generates the invoice. The entire self-service process occurs without the need for staff intervention. This RFID-enabled checkout system not only saves time for customers but also helps reduce labor costs at the checkout counter.

4. UNIQLO, RFID, and New Retail

The New Retail platform is a technological solution that helps automate most operational tasks, increases sales efficiency, and reduces the time it takes for goods to move from manufacturing or distribution centers to end customers. It also allows businesses to proactively plan distribution and sales strategies based on faster and more detailed demand forecasting. Every element of the distribution system gains access to end customers and can allocate resources to manage the retail chain in a modern, efficient, and real-time manner.

Fashion trends evolve rapidly, making supply chain performance critical to meeting customer demand. This is especially true for retail companies, where a drop in operational efficiency or logistics performance can affect the entire business. By using RFID technology to track production, sales, and inventory in real time, UNIQLO is able to collect and analyze data to supply products that consumers truly want, while also planning raw material procurement and inventory based on actual demand.

For example, with real-time sales and inventory data enabled by RFID, when a product’s sales spike, operators can immediately decide to order more materials and ramp up production. As a result, products are always in stock and delivered to customers quickly.

According to industry reports, after implementing the RFID system, average warehouse and stock operations that previously required 100 staff were reduced to just 10—cutting labor costs by 90%. Meanwhile, UNIQLO’s production efficiency increased 80 times, delivery productivity rose 19 times, inventory turnover improved 3 times, employee training costs dropped by 80%, and inventory tracking accuracy reached 99.99%.

5. RFID Adoption in Vietnam’s Retail Sector

Despite its proven benefits, the adoption of RFID in Vietnam remains relatively modest. Most businesses are still accustomed to barcode systems, have limited exposure to RFID technology, and are concerned about upfront investment costs.

1Gate has experience implementing both large- and small-scale RFID projects across Vietnam and is ready to advise on tailored solutions based on the specific operational conditions of any business in any industry. Additionally, 1Gate is currently offering support programs for SMEs undergoing digital transformation, including free RFID tags and complimentary software. Please contact us for consultation.

Email: info@1gate.com.vn

Phone: (028) 3932 0445

Related Articles

- 1Gate’s RFID-Based Traceability & Anti-Counterfeiting System

- Hệ thống truy xuất nguồn gốc và chống giả 1Gate

- RFID Applications in Steel Manufacturing Plants

- Choosing RFID Tags for Metal Surfaces – What You Need to Know

- Walmart, RFID, and the New Retail Strategy

- Ứng dụng RFID trong nhà máy sắt thép

- Lựa chọn thẻ RFID gắn trên kim loại- Những điều cần lưu ý

- UNIQLO áp dụng RFID trên phạm vi toàn cầu

- Wallmart, RFID và chiến lược New Retail